Mobile, Technology, and Business news

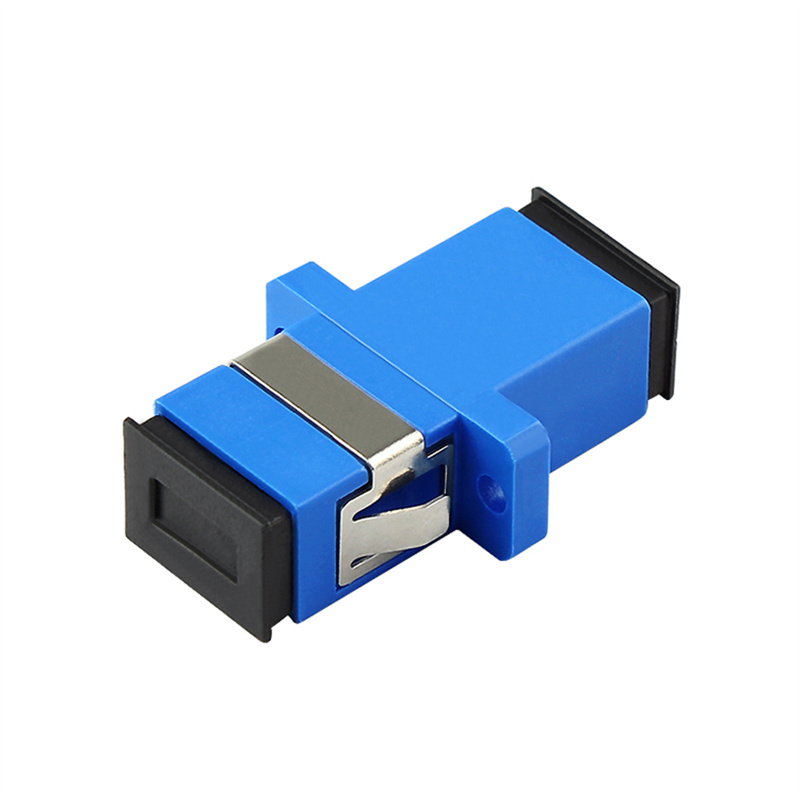

During electrical works, there are times when cable technicians may opt for a cable splice instead of getting new cables. Cable splicing provides the opportunity of using damaged cables instead of new installations, providing a cheaper alternative. However, to splice cables, you’ll need a certain level of knowledge. Optic Patchcord

In this guide, you’ll learn what cable splicing is all about and how to splice cables effectively.

Cable splicing involves connecting the endpoints of electrical cables and fiber optic cables. When splicing cables, cable technicians join different electrical wires together, while retaining their previous properties. The main aim is for the spliced wires to conduct electrical current.

Cable splicing is used in many industries, including the rail industry for electrical connections.

A cable splicing technique can also be performed to expand electrical cables or fiber optic cables to reach an electrical circuit. You can splice cables when heading a branch circuit in different directions or when expanding fixture boxers.

There are two types of cable splicing: mechanical splicing and fusion splicing. For electrical connections on train tracks, mechanical splicing is applicable. On the other hand, you can splice fiber optic cables through mechanical or fusion splicing.

Mechanical splicing involves joining electrical cables or fiber optic cables manually. Unlike fusion splicing, you do not need a special electrical device or a fusion splicer to join the cables. In mechanical splicing, the connection is adjusted and kept in place by an assembly using an index-matching fluid.

To fasten the splicing process, a covering is used. It can either be a snap-type cover or an adhesive cover. Usually, the mechanical splice for connecting the fibers is about 2.36 inches long and 0.39 inches in diameter. This aligns two bare cables and secures them. In mechanical splicing, the fibers are not joined permanently but are only held in place for current or light to pass through.

Usually, the insertion loss is less than 0.5dB, while the splicing loss is typically around 0.3dB. However, fiber mechanical splicing brings about higher reflection than fusion splicing. For fiber optics, the mechanical splices are easy to handle, compact, and suitable for long-term installations or fast repairs.

Mechanical splices can be used for both multimode and single-mode fibers. Though mechanical splicing is easy to make, the insertion loss is higher. There are certain benefits of mechanical splicing. First, it does not require electricity and can easily be performed manually. Also, it does not require much equipment compared to fusion splicing. Lastly, mechanical splicing allows you to make a cable splice in situations where fusion splicing is impractical.

Fusion splicing, on the other hand, is permanent but costs more than mechanical splicing. In fusion splicing, cable technicians use a unique type of fusion splicer machine to join the two fibers. Fusion splicing is usually done by experienced technicians.

If the fibers are not connected properly, it may result in signal degradation. The fibers are fused with smaller transmission loss and less attenuation than in mechanical splicing. The insertion loss is less than 0.1dB, while the transmission loss is typically 0.1dB for both multimode and single-mode fiber cables.

The fiber ends are then connected through heat by creating an electrical arc. The electric arc melts the fibers and joins them together. Fusion splicing has certain benefits. First, it has a lower insertion loss and back reflection than mechanical splicing. Also, unlike mechanical splicing, it’s permanent and has a higher mechanical strength.

The spliced cables can withstand a wide temperature range, while the optical path is protected from dust and irritants. However, fusion splicing is more complex than mechanical splicing. Also, it’s not suitable for temporary connections due to the process involved.

Steps for Building a Splice

To build a splice, you’ll need splice kits containing accessories such as wire cutters, connectors, sealant, cleaners, etc. Whenever you are splicing a cable, it’s important to turn the power off in the circuit. Below are the steps for building a splice.

The first step is fiber preparations. When performing a mechanical splice, remove protective coatings, tubes, and other materials. You can strip wires before splicing or apply a twist-on wire cap.

The next step is to cut the wires. You can do this by using wire cutters to grab and cut through the wires. Heavy gauge wires will require heavier cutters. Some wire cutters may have wire strippers under the bland or in the handle. Wire strippers are used for removing the protective coatings around wires. They are usually made of steel with serrated teeth to allow easy stripping.

After this, join the fibers mechanically. Unlike fusion splicing, mechanical splicing does not require any heat.

If you’re using a twist-on wire cap, you can join the wires and the wire caps with electrical tape. You can then reshield and jacket the wires.

Just like mechanical splicing, the first step is to strip the protective layers around the fiber cable. You can do this with a wire stripper. After exposing the raw fiber, the next step is to clean the fiber. You can use lint-free wipes or a 99.9% isopropyl alcohol solution to clean the glass.

The next step is to break the fiber with a chopper knife. After splitting the fibers, join them together with a fusion splicer. In fusion splicing, you’ll need to create an electric arc to melt the fibers after aligning them correctly. This permanently joins the fiber cables together.

After fusing the fiber, it should be protected from weather and breakage through silicone gel or shrink tubing.

Fusion splicing is best done by qualified applicants to ensure safety and successful splicing.

To sum up, cable splicing involves joining electric or fiber optic cables together while keeping their previous properties. Mechanical splicing and fusion splicing are the two main methods of splicing.

Both types have their benefits and drawbacks. Mechanical splicing is easier and requires less equipment than fusion splicing. However, fusion splicing is permanent though it requires more skill compared to mechanical splicing.

You should have the necessary splice kits when performing cable splicing. Lastly, if you do not have the required level of knowledge, it’s better to contact a cable technician, especially to perform fusion splicing.

Filed Under: Around the Web

See More Editor's Picks...

Fiber Optic Distribution Box More Posts from this Category